In today's fast-paced business environment, companies are constantly seeking ways to differentiate themselves from competitors and drive efficiency in their production processes. One key area that offers a significant competitive edge is innovative formulation manufacturing. By harnessing advanced technologies and creative approaches, businesses can develop unique formulations that not only meet consumer demands but also optimize production costs and enhance product performance. This blog will explore the essential strategies and best practices in formulation manufacturing, providing insights into how organizations can leverage innovation to create superior products. From understanding market trends to implementing cutting-edge techniques, unlocking the potential of formulation manufacturing could be the game-changer your company needs to thrive in a crowded marketplace.

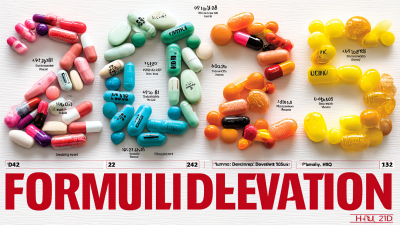

Innovative formulation manufacturing plays a crucial role in helping companies achieve market leadership in today’s competitive landscape. According to a report by Grand View Research, the global formulation development market is projected to reach USD 118.04 billion by 2027, growing at a CAGR of 7.3%. This growth is driven by the increasing demand for tailored solutions in sectors such as pharmaceuticals, cosmetics, and food, where consumers are seeking products that not only meet their needs but also stand out in terms of efficacy and sustainability.

To gain a competitive edge, companies are leveraging advanced formulation technologies that enhance product performance and reduce time to market. For instance, the use of nanotechnology in formulation has shown to improve drug delivery systems, leading to higher bioavailability and patient compliance. Furthermore, a study from MarketsandMarkets highlights that 70% of consumers consider product formulation as a key factor in their purchasing decisions. This shift underscores the importance of innovative manufacturing practices that not only improve product quality but also align with evolving consumer preferences, ensuring that businesses remain ahead of the curve in their respective markets.

Digital technology is transforming formulation processes, providing manufacturers with a competitive edge in an increasingly demanding market. The incorporation of advanced software and automation into formulation manufacturing enhances precision and efficiency. By utilizing digital tools such as artificial intelligence and machine learning, companies can optimize formulations based on real-time data analysis, leading to improved product performance and reduced time to market.

Moreover, digital technology facilitates better collaboration among teams, breaking down silos and streamlining communication. Cloud-based platforms allow scientists and engineers to share insights and data instantly, fostering a culture of innovation. This accessibility to information accelerates the iteration process, empowering teams to experiment with new formulations and react swiftly to market changes. As a result, businesses not only enhance their existing products but also pave the way for groundbreaking solutions that meet evolving consumer demands.

In addition, the integration of digital technologies can significantly reduce waste and resource consumption. By employing simulation tools, manufacturers can accurately predict outcomes and refine formulations before actual production, minimizing trial-and-error waste. This not only leads to cost savings but also aligns with sustainable practices, appealing to environmentally conscious consumers. Overall, digital technology in formulation processes is a key driver of efficiency, collaboration, and sustainability, fundamentally transforming the landscape of manufacturing.

In the competitive landscape of manufacturing, customization plays a pivotal role in enhancing product performance and customer satisfaction. According to a report by McKinsey & Company, 70% of consumers are willing to pay a premium for personalized products. This underscores the importance of innovative formulation manufacturing, where tailored solutions not only meet specific market needs but also drive loyalty among consumers. By leveraging advanced technologies and R&D capabilities, businesses can create customized formulations that align closely with customer preferences, leading to improved satisfaction rates.

When considering innovative formulations, it's essential to focus on a few key tips. First, invest in comprehensive market research to understand consumer demands and trends. This will guide the development of products that resonate well with your target audience. Second, consider adopting flexible manufacturing processes that enable rapid prototyping and adjustments. This agility allows manufacturers to respond quickly to feedback and changing market conditions, thus ensuring that the final product consistently meets customer expectations.

Moreover, collaborating with customers during the development process can yield valuable insights. Engaging customers through surveys and feedback loops not only helps in refining formulations but also fosters a sense of ownership among consumers. When customers feel involved in the creation process, their satisfaction and loyalty are likely to increase, ultimately giving businesses a competitive edge in the market.

Innovative formulation manufacturing is revolutionizing the production landscape, providing significant time and cost benefits that enable businesses to streamline their processes. By adopting advanced technologies and methodologies, companies are able to enhance efficiency, reduce wastage, and optimize resource utilization. For instance, the integration of automation and real-time monitoring enables a more precise control over the manufacturing process, minimizing errors and the need for extensive rework. This results in quicker turnaround times, allowing firms to meet market demands more effectively.

Moreover, innovative manufacturing techniques can significantly reduce production costs. Techniques such as continuous manufacturing and modular production help in lowering overhead costs by maximizing equipment utilization and minimizing downtime. This not only leads to substantial savings but also allows for greater scalability, enabling companies to adjust production volumes easily based on market fluctuations. As businesses seek to gain a competitive edge, embracing innovative formulation manufacturing is not just a choice; it is a strategic imperative that unlocks both time efficiency and cost savings, driving long-term growth and sustainability.

Sustainable practices are at the forefront of innovative formulation manufacturing, significantly enhancing both efficiency and environmental responsibility. One of the most impactful strategies is the integration of renewable resources, which not only reduces dependency on finite materials but also minimizes the carbon footprint. Companies that adopt bio-based ingredients reflect a commitment to sustainability, appealing to eco-conscious consumers and meeting regulatory demands for greener products. This shift not only supports global sustainability efforts but can also lead to cost savings in the long run, as renewable materials often become more economically viable with technological advancements.

Additionally, the implementation of waste reduction techniques in formulation processes contributes to a more circular economy. By rethinking processes to minimize waste generation and promote recycling, manufacturers can optimize their supply chains and resource usage. Tools such as life cycle assessments further aid in identifying areas for improvement, enabling companies to track their environmental impact effectively. Moreover, sustainable practices foster innovation; by challenging conventional methods, manufacturers are often led to discover novel formulations that not only meet performance standards but also resonate with a sustainable ethos.

This versatility in product development further solidifies a company's competitive edge in a market that increasingly values sustainability.