The pharmaceutical manufacturing process is a critical component of the healthcare industry, significantly impacting the quality and delivery of medications to patients. To enhance efficiency in this process, experts emphasize the importance of embracing modern technologies and methodologies. Dr. Emily Richards, a leading authority in pharmaceutical engineering, asserts that "streamlining operations and adopting innovative solutions can significantly reduce costs and improve production timelines." Her insights underscore the necessity for manufacturers to continuously evolve and integrate advanced techniques that optimize every stage of production.

In today's dynamic market, the pressure to increase efficiency while maintaining high standards of quality has never been greater for pharmaceutical manufacturers. By refining the pharmaceutical manufacturing process, companies can not only enhance output but also ensure compliance with stringent regulatory requirements. This is essential in addressing the growing demand for pharmaceuticals, especially in the wake of global health challenges.

Thus, focusing on the optimization of the pharmaceutical manufacturing process is paramount. It requires a commitment to training, investment in technology, and a strategic approach to workflow management. As the industry continues to evolve, the drive towards efficiency will play a pivotal role in shaping the future of pharmaceutical manufacturing.

The pharmaceutical manufacturing industry faces several significant challenges that hinder efficiency and productivity. One major hurdle is the increasing complexity of production processes resulting from stringent regulatory requirements and the need for advanced technologies. According to a report by McKinsey & Company, nearly 75% of pharmaceutical manufacturers report that navigating regulatory compliance is a primary concern, often leading to delays and increased costs. This complexity not only impacts time-to-market but also necessitates ongoing training and adaptation from the workforce, further straining resources.

Another critical challenge is the rising costs associated with raw materials and production. A study by the IQVIA Institute for Human Data Science highlights that the operational expenses in pharmaceutical manufacturing have surged by 20% over the past five years, driven by both inflationary pressures and the demand for higher-quality inputs. Additionally, supply chain disruptions, exacerbated by global events such as the COVID-19 pandemic, have highlighted vulnerabilities that hinder timely production and delivery of essential medications. As manufacturers seek to streamline operations, addressing these challenges is essential for improving overall efficiency and ensuring the sustainability of the pharmaceutical supply chain.

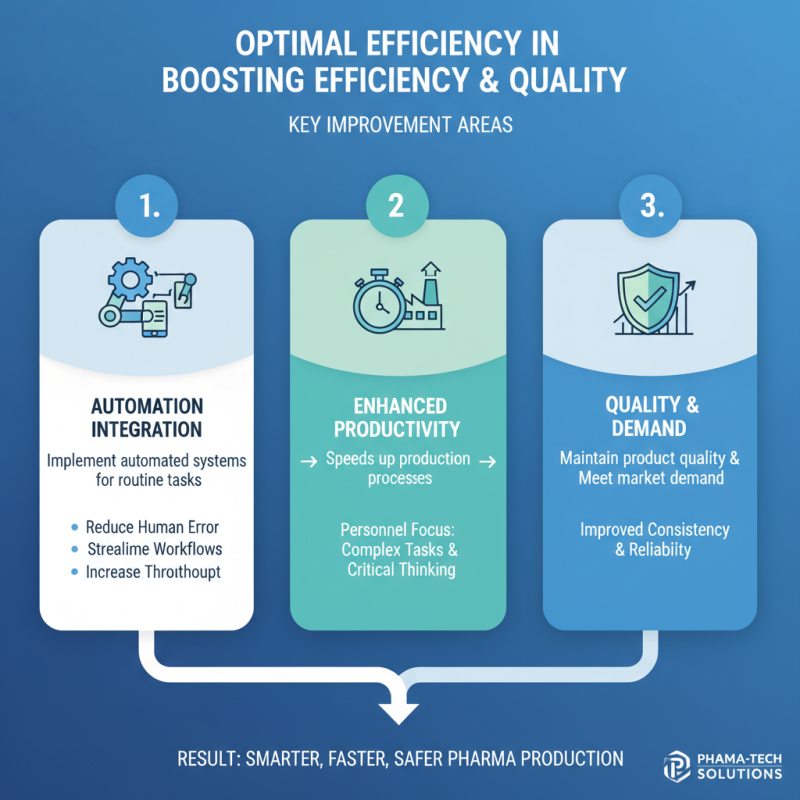

In the pharmaceutical manufacturing industry, achieving optimal efficiency is crucial to meeting demand and maintaining product quality. Identifying key areas for improvement can significantly enhance production processes. One primary area is the integration of automation technologies. By implementing automated systems for routine tasks, manufacturers can reduce human error, streamline workflows, and increase overall throughput. This automation not only speeds up production but also allows personnel to focus on more complex tasks that require critical thinking.

Tips: Consider conducting a thorough assessment of your current technologies and processes. Invest in robust automation solutions that can be scaled based on production needs. Additionally, provide training for staff to ensure they can effectively handle new technologies.

Another important aspect is optimizing supply chain management. Efficient procurement and inventory management can mitigate delays and reduce costs. By collaborating closely with suppliers and utilizing predictive analytics, manufacturers can make informed decisions regarding raw material requirements, ensuring that inventory levels are aligned with production schedules.

Tips: Develop strong relationships with vendors to enhance communication and reliability. Utilizing inventory management software can also help track materials in real-time, minimizing wastage and ensuring timely availability of resources.

Implementing Lean Manufacturing Principles in the pharmaceutical sector is crucial for driving efficiency and reducing waste. Lean manufacturing focuses on optimizing processes by minimizing non-value-adding activities, which can lead to significant improvements in productivity. In the pharmaceutical industry, this approach involves examining each step of the production process—from raw material handling to distribution—identifying areas where time and resources are wasted, and re-engineering workflows to enhance overall efficiency.

One effective method is to employ Value Stream Mapping (VSM), which allows manufacturers to visualize their processes and highlight inefficiencies. By engaging teams in continuous improvement practices, pharmaceutical companies can foster a culture of innovation and problem-solving. For instance, implementing just-in-time (JIT) inventory management can reduce excess stock and lower storage costs, ensuring that materials are available when needed without overcommitting resources. Additionally, regular training and development of staff in lean methodologies promote accountability and a proactive approach to eliminating waste, ultimately leading to faster cycle times and improved product quality.

In today's competitive pharmaceutical landscape, optimizing manufacturing processes is crucial for achieving better efficiency. Technology and automation play a pivotal role in streamlining operations, reducing human error, and enhancing production speed. By incorporating advanced technologies such as artificial intelligence, machine learning, and robotics, manufacturers can significantly improve their workflow and resource management.

Tips for leveraging technology in pharmaceutical manufacturing include investing in automated systems that manage production lines and inventory in real time. This not only minimizes downtime but also allows for precise tracking of resources, leading to a more efficient use of materials. Additionally, utilizing data analytics can help identify bottlenecks in the process, enabling proactive adjustments that enhance overall productivity.

Another important aspect is the integration of Internet of Things (IoT) devices, which can monitor equipment performance and predict maintenance needs. By implementing predictive maintenance strategies, companies can reduce unexpected breakdowns, ensuring a smoother operation. Training staff to effectively use these technologies further amplifies their impact, leading to a culture of continuous improvement and operational excellence.

| Process Stage | Current Efficiency (%) | Optimized Efficiency (%) | Technology Used | Comments |

|---|---|---|---|---|

| Raw Material Handling | 75 | 90 | Automated Stock Management System | Reduction in material waste. |

| Production Scheduling | 68 | 85 | Advanced Planning and Scheduling (APS) Software | Optimized resource allocation. |

| Quality Control | 70 | 92 | Real-time Monitoring Systems | Faster detection of quality issues. |

| Packaging and Labeling | 80 | 95 | Automated Packaging Machines | Increased speed and accuracy. |

| Supply Chain Management | 65 | 88 | Supply Chain Optimization Software | Improved logistics and inventory control. |

In the pharmaceutical industry, measuring and analyzing

performance metrics is crucial for optimizing manufacturing processes and improving overall efficiency. Key

performance indicators (KPIs) such as cycle time,

yield rates, and

equipment utilization provide essential insights

into production workflows. According to a report from the International Society for Pharmaceutical Engineering (ISPE),

optimizing cycle time can lead to a 15-20% increase in

productivity, which ultimately translates into significant cost savings and enhanced competitiveness in

the market.

Additionally, real-time data analytics plays a vital role

in pharmaceutical production. Employing advanced analytics tools allows manufacturers to monitor KPIs

continuously, identify bottlenecks, and take proactive measures to address inefficiencies. A study by

McKinsey & Company highlights that organizations leveraging data

analytics in their production processes can improve operational efficiency by up to 30%.

This paradigm shift towards data-driven decision-making not only enhances process performance but also ensures

compliance with stringent regulatory requirements, thereby reducing the risk of costly operational setbacks.