Formulation Manufacturing is a critical process in the production of various products, including pharmaceuticals, cosmetics, and food items. Dr. Emily Chen, a leading expert in this industry, once said, "Successful formulation manufacturing is an art and science combined." This statement underscores the complexity involved in developing effective products.

In Formulation Manufacturing, precision is paramount. Every ingredient matters. The blending of raw materials requires careful consideration of their properties and interactions. This is where challenges often arise. Miscalculations can lead to undesirable outcomes. An effective formulation must achieve efficacy and stability while meeting regulatory standards.

Understanding Formulation Manufacturing involves recognizing its dynamic nature. It is a process that demands constant adjustment and innovation. As markets evolve, so do consumer needs. In this vibrant landscape, companies must strike a balance between creativity and compliance. Observing industry trends is essential, but sometimes the pursuit of a perfect formulation leads to unforeseen obstacles.

Formulation manufacturing plays a critical role in many industries. It involves the process of combining various raw materials to create a final product. This can be seen in areas like pharmaceuticals, food and beverage, and personal care products. According to a report by Grand View Research, the global formulation manufacturing market is expected to reach $674.1 billion by 2027, growing at a CAGR of 7.5%.

The formulation manufacturing process includes several stages. First, companies must select the right ingredients based on desired properties. Each ingredient can significantly affect the final product's performance. Then, thorough testing is necessary. Quality assurance ensures that products meet safety and efficacy standards. However, many companies face challenges during this phase. Limited resources and inconsistent supplier quality can lead to delays and product failures.

Data from MarketsandMarkets indicates that over 30% of product launches fail due to formulation issues. This highlights the importance of precise formulation techniques. The process requires continuous refinement based on feedback and market trends. A focus on innovation is vital, yet many teams struggle to balance creativity with regulatory requirements.

This bar chart illustrates the typical time spent in various phases of formulation manufacturing, from raw material sourcing to distribution. Each phase is critical in ensuring the final product meets quality standards and customer expectations.

Formulation plays a crucial role in product development across various industries. It involves creating a product by combining multiple ingredients to achieve desired characteristics. The right formulation can enhance effectiveness and stability, while a poor one may lead to product failure. According to a market report by Grand View Research, the global formulation market is expected to reach USD 684 billion by 2025. This underscores the importance of getting the formulation right from the outset.

In many instances, formulation development requires rigorous testing and adjustments. Experts must analyze ingredient interactions and their impact on overall performance. A study by McKinsey indicates that 90% of product launches fail due to formulation issues. This highlights the need for manufacturers to prioritize formulation in their development process.

However, the challenge lies in the complexity of formulations. The balance between ingredients can be delicate. Sometimes, desired attributes can conflict with each other. For example, achieving both increased shelf life and superior sensory quality can be difficult. This necessitates a commitment to continuous improvement in formulation methods. A reflective approach can guide researchers to explore innovative solutions to these recurring issues.

| Formulation Type | Key Ingredients | Application Area | Benefits |

|---|---|---|---|

| Cosmetic Creams | Emollients, Preservatives, Fragrances | Skin Care | Hydration, Preservation of Shelf Life |

| Pharmaceutical Tablets | Active Pharmaceutical Ingredients, Binders, Disintegrants | Medicinal Products | Controlled Release, Dosage Accuracy |

| Food Supplements | Vitamins, Minerals, Flavoring Agents | Health and Nutrition | Enhanced Nutritional Benefits |

| Industrial Coatings | Pigments, Solvents, Resins | Construction, Manufacturing | Durability, Aesthetic Appeal |

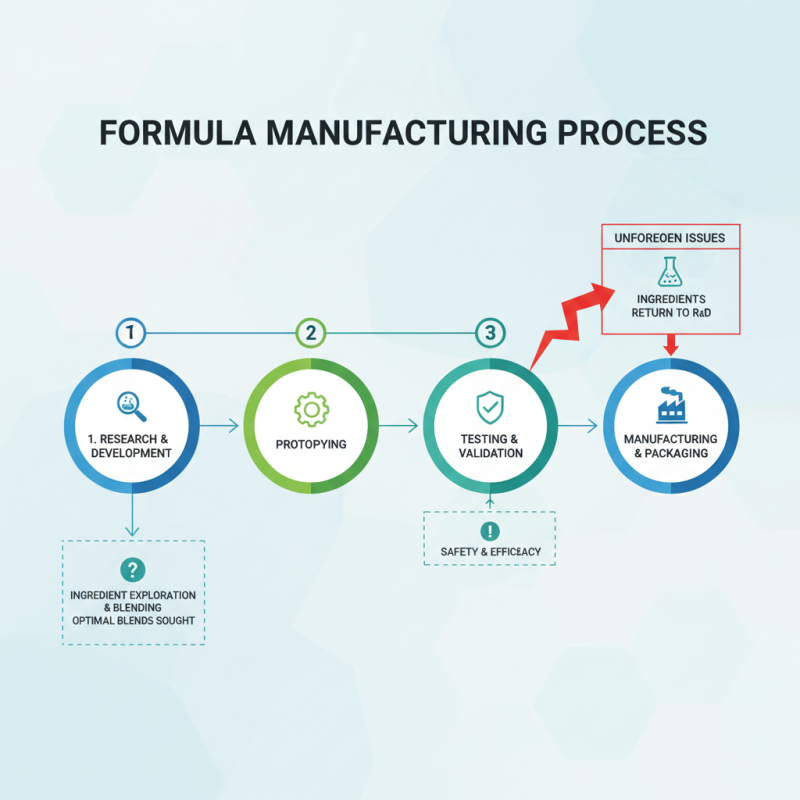

Formulation manufacturing is a complex process that involves several key steps. It begins with research and development. This phase is crucial. Scientists explore ingredients and their interactions. They look for optimal blends. Prototypes are created based on these findings. Testing follows to ensure safety and efficacy. However, unforeseen issues can arise. Sometimes, ingredients don't behave as expected.

Once the formulation is stable, the production phase begins. Raw materials are sourced carefully. Quality control checks are vital throughout this stage. Each batch of ingredients must meet specific standards. Mixing equipment is calibrated meticulously. There is often room for error. Variations in measurements can lead to inconsistent products. The environment also plays a role. Humidity and temperature can affect results.

After production, packaging is another critical process. It protects the product and maintains its integrity. Packaging design must appeal to consumers but also be functional. There are sustainable options to consider as well. This complexity makes formulation manufacturing a blend of art and science. Each step requires attention to detail and reflection on potential improvements.

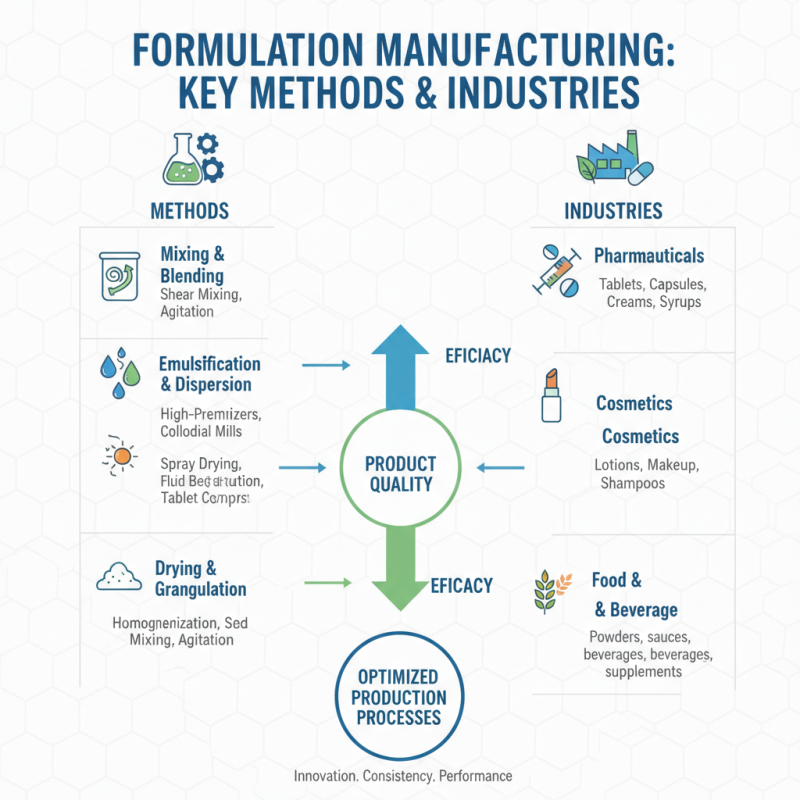

Formulation manufacturing plays a vital role in various industries, particularly in pharmaceuticals, cosmetics, and food production. The methods used in formulation manufacturing can significantly impact product quality and efficacy. Understanding these methods is essential for optimizing production processes.

One common method is batch processing. In batch processing, ingredients are mixed in specific quantities to create the final product. This approach allows for precise control over formulation. According to a report by MarketsandMarkets, the batch processing market is projected to grow from USD 7.5 billion in 2020 to USD 11.5 billion by 2025. However, the challenge lies in maintaining consistency across batches, which can lead to variations in product quality.

Another approach is continuous processing. This method involves producing goods continuously, rather than in discrete batches. Continuous processing can improve efficiency and reduce waste. However, it requires a robust system to ensure quality control. An article from the International Journal of Pharmaceutics states that continuous processing can increase production rates by up to 30%. Yet, it also poses challenges, such as complex equipment and the need for skilled operators. Balancing speed, quality, and cost remains a struggle in this method.

Formulation manufacturing faces a variety of challenges. One key issue is precision. Achieving the right balance of ingredients can be difficult. Small variations can lead to big problems. This inconsistency affects product quality. Companies constantly seek methods to improve precision in formulations.

Innovation plays a crucial role in overcoming these challenges. New technologies, such as automation and AI, help streamline processes. These advancements allow for more accurate measurements and quicker adjustments. However, integrating such technologies isn’t always straightforward. There are often technical hurdles and employee training needs. Adapting to new systems may cause temporary disruptions.

Moreover, regulatory compliance remains a significant concern. Manufacturers must navigate complex guidelines. Staying informed about changing regulations is essential. Sometimes, innovations can clash with these rules, leading to delays. Companies must find a balance between innovation and compliance to thrive in the formulation manufacturing landscape. Reflecting on these challenges can inspire new solutions and ideas for improvement.