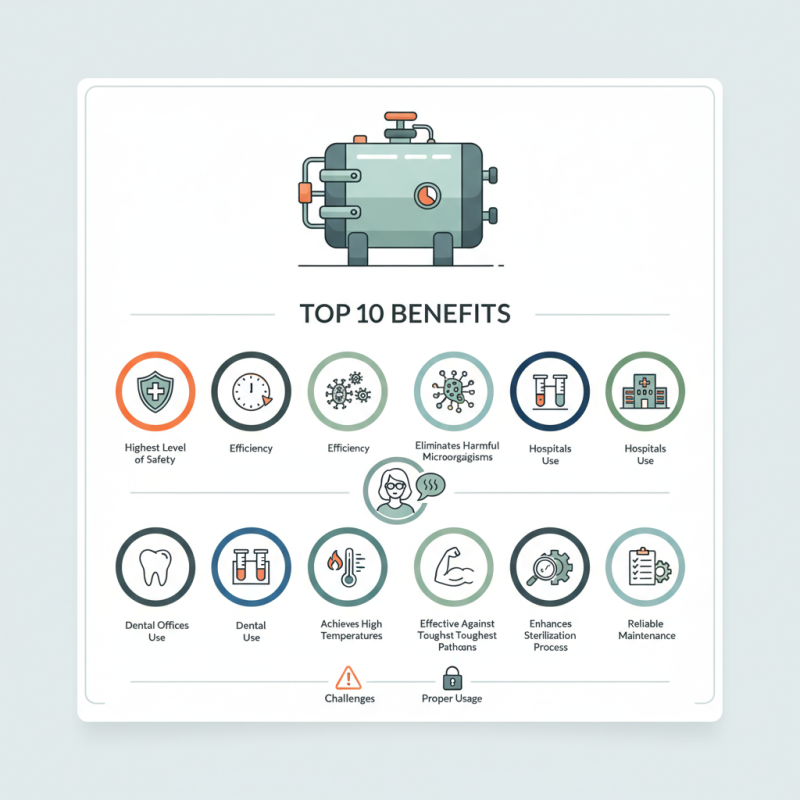

In the field of sterilization, the "Autoclave Vessel" stands out as a vital tool. Dr. Emily Carter, a leading expert in sterilization technology, states, “An autoclave vessel is essential for ensuring the highest level of safety and efficiency in medical environments.” This statement underscores the importance of using autoclaves for reliable sterilization.

Autoclave vessels utilize steam and pressure to eliminate harmful microorganisms. They are commonly used in hospitals, laboratories, and dental offices. The ability to achieve high temperatures makes them effective against even the toughest pathogens. Yet, many facilities still do not fully appreciate their potential. The nuances involved in proper usage require careful consideration.

Investing in an autoclave vessel can enhance the sterilization process significantly. However, it is crucial to maintain the equipment regularly. Failure to do so can lead to ineffective sterilization. Understanding the benefits while acknowledging the challenges is key to maximizing the use of an autoclave vessel.

High-temperature sterilization in autoclave vessels offers numerous advantages. One major benefit is the ability to eliminate a wide range of microorganisms. Bacteria, viruses, and spores are all effectively killed using steam heat. This method is reliable and often faster than traditional sterilization techniques. The steam penetrates materials, ensuring thorough sterilization.

Another significant aspect is the ability to handle various materials. Glass, metals, and certain plastics can all be sterilized effectively. However, not all plastics tolerate high temperatures. Users must be cautious and understand the limits of the materials they are working with. Sometimes, residual moisture can affect the outcome, making it essential to monitor cycles carefully.

Moreover, high-temperature sterilization promotes safety in healthcare settings. By eliminating pathogens, the risk of infection reduces substantially. Contaminated instruments can lead to severe complications for patients. Yet, one must recognize that improper use can lead to failures. Users need to maintain their equipment and follow protocols diligently for the best results. Understanding these nuances is critical in leveraging the full potential of autoclave sterilization.

Steam pressure is a powerful tool for sterilization. An autoclave vessel utilizes this principle effectively. By applying high temperatures and pressure, it eliminates harmful microorganisms. Research indicates that autoclaving can kill bacteria, viruses, and fungi within minutes, ensuring safety in medical and laboratory settings.

According to a study by the Association for the Advancement of Medical Instrumentation (AAMI), proper autoclaving achieves a minimum of 99.9999% microbial reduction. This level of effectiveness is crucial for preventing infections. However, operators must remain vigilant. Any lapse in procedure can lead to contamination risks. Equipment malfunction or improper packaging can compromise results.

Interestingly, some believe that manual methods suffice for sterilization, but data suggests otherwise. Steam sterilization's reliability makes it a golden standard. Still, it requires training and commitment. Regular maintenance of autoclave machines is essential to ensure optimal performance. Overlooking this can lead to inefficiencies that endanger health and safety. Thus, every step in the process matters for effective microbial elimination.

Autoclaves are invaluable for sterilization across various fields, including healthcare and laboratories. Their versatility in handling different instruments and materials is notable. According to a 2020 industry report, more than 80% of healthcare facilities utilize autoclaves for instrument sterilization. This versatility allows them to sterilize surgical tools, laboratory glassware, and even certain fabrics effectively.

One distinct feature of autoclaves is their ability to work with diverse materials. They can easily process metals, plastics, and porous materials alike. However, not all materials can withstand high temperatures or steam pressure, which requires careful selection and training. Around 15% of users report challenges in determining the right materials for autoclaving. This gap often raises questions about safety and effectiveness in sterilization.

Moreover, while autoclaves do a remarkable job, they are not without limitations. Some instruments may be damaged under high heat. In fact, about 10% of users experience equipment failure due to incorrect settings or material incompatibility. Regular training and audits can help mitigate these issues, ensuring safety and reliability in a sterile environment. This ongoing adjustment is vital for maintaining a high standard of sterilization across various tools and settings.

| Benefit | Description | Suitable Materials | Applications |

|---|---|---|---|

| Effective Sterilization | Achieves up to 100% sterility for tools. | Metal, glass, certain plastics | Medical and laboratory instruments |

| Time Efficiency | Fast cycle times compared to other methods. | Various surgical instruments | Hospitals, clinics |

| Versatility | Can sterilize liquids, solids, and porous materials. | Liquid solutions, powders | Pharmaceuticals, research labs |

| Safety | Minimizes the risk of contamination. | Heat-resistant materials | Food industry, medical fields |

| Cost-Effectiveness | Reduces costs of disposables by reusing tools. | Metal instruments | Dental practices, veterinary clinics |

| Environmental Impact | Reduces waste through reusable items. | Reusable materials | Eco-friendly practices |

| User-Friendly | Generally easy to operate with simple controls. | Standard laboratory and medical tools | Educational institutions, training centers |

| Regulatory Compliance | Meets industry standards for sterilization. | All sterilizable items | Healthcare environments |

| Traceability | Allows tracking of sterilization cycles. | Traceable materials | Quality assurance processes |

| Quality Control | Ensures consistent results with regular monitoring. | All sterilization applicable items | Manufacturing sectors |

Using an autoclave vessel for sterilization offers a range of advantages, particularly in reducing chemical use. Autoclaves utilize high-pressure steam to disinfect materials. This method significantly lowers the reliance on harsh chemicals. Many traditional sterilization methods rely heavily on toxic substances that can be harmful to both the environment and human health.

For instance, consider the impact of using bleach or formaldehyde. These chemicals can pollute air and water. In contrast, with an autoclave, steam sterilization is clean and efficient. It does not leave behind harmful residues. Moreover, it saves time by swiftly handling a large volume of items.

However, we must reflect on the energy consumption of autoclaves. This is an area worth examination. The steam generation requires a significant amount of energy. Balancing efficiency with environmental responsibility is critical. We should strive to optimize usage to minimize the carbon footprint. Overall, while autoclaves present an eco-friendly option, ongoing improvements are necessary for sustainability.

Autoclaves are becoming essential in healthcare and laboratory settings. They significantly enhance workflow efficiency. A recent study found that autoclaves can reduce sterilization time by up to 30%. This time saving leads to faster processing of instruments and supplies. In busy environments, every minute counts when it comes to patient care.

The rapid sterilization cycles of autoclaves can increase productivity. Traditional sterilization methods often take hours. In contrast, many autoclaves complete a cycle in just 15 to 30 minutes. This efficiency can drastically affect daily operations. Yet, not all facilities fully realize this potential. Some may hesitate in adopting autoclaves because of initial investment costs.

Moreover, the effectiveness of sterilization cycles is crucial. Many laboratories report inconsistencies in traditional methods. Autoclaves provide reliable results, ensuring equipment is ready when needed. That said, regular maintenance and operator training are necessary. Neglecting these could lead to mishaps and undermine productivity. Regular inspection and well-trained staff are key to maximizing the benefits of autoclaves.